Hlobo

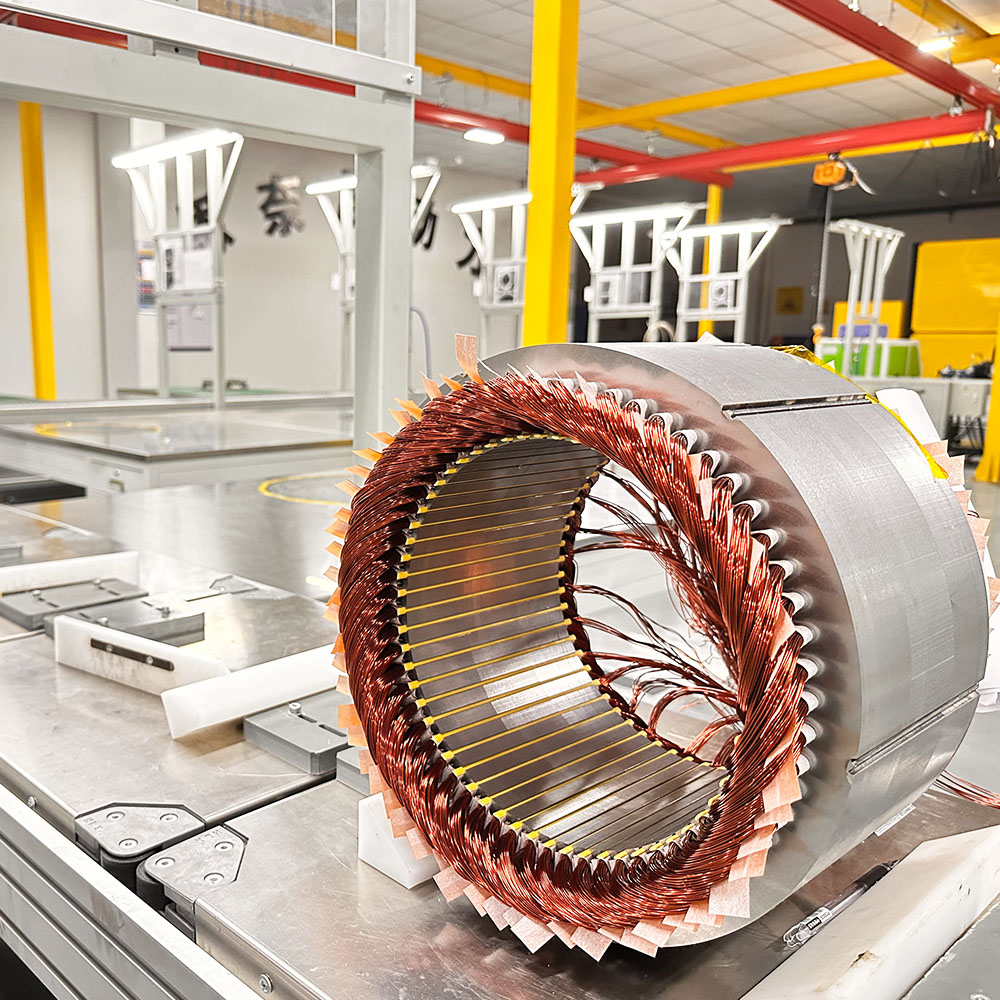

Re na le ho putlama ha motho a le mong, 'me re ntse re putlama, le lebelo le lebelo le phahameng haholo ho fihlela litlhoko tsa li-cartors tse fapaneng. Hoo e ka bang 90% ea ronaLi-LOmiminotion tsa Mollo li entsoe ka lits'oants'o. Nakong ea sebopeho sa bold, baemini ba rona ba litsebi ba tla li khetha ho tlala litlhahiso tse ling tsa bareki ho bareki ba khotsofatsang ba khotsofatsang.

Mehlala e etsang

Re ka kopana le boholo bo fapaneng le theknoloji ea litemana tsa litemana tsa makoloi tsa makoloi.

A

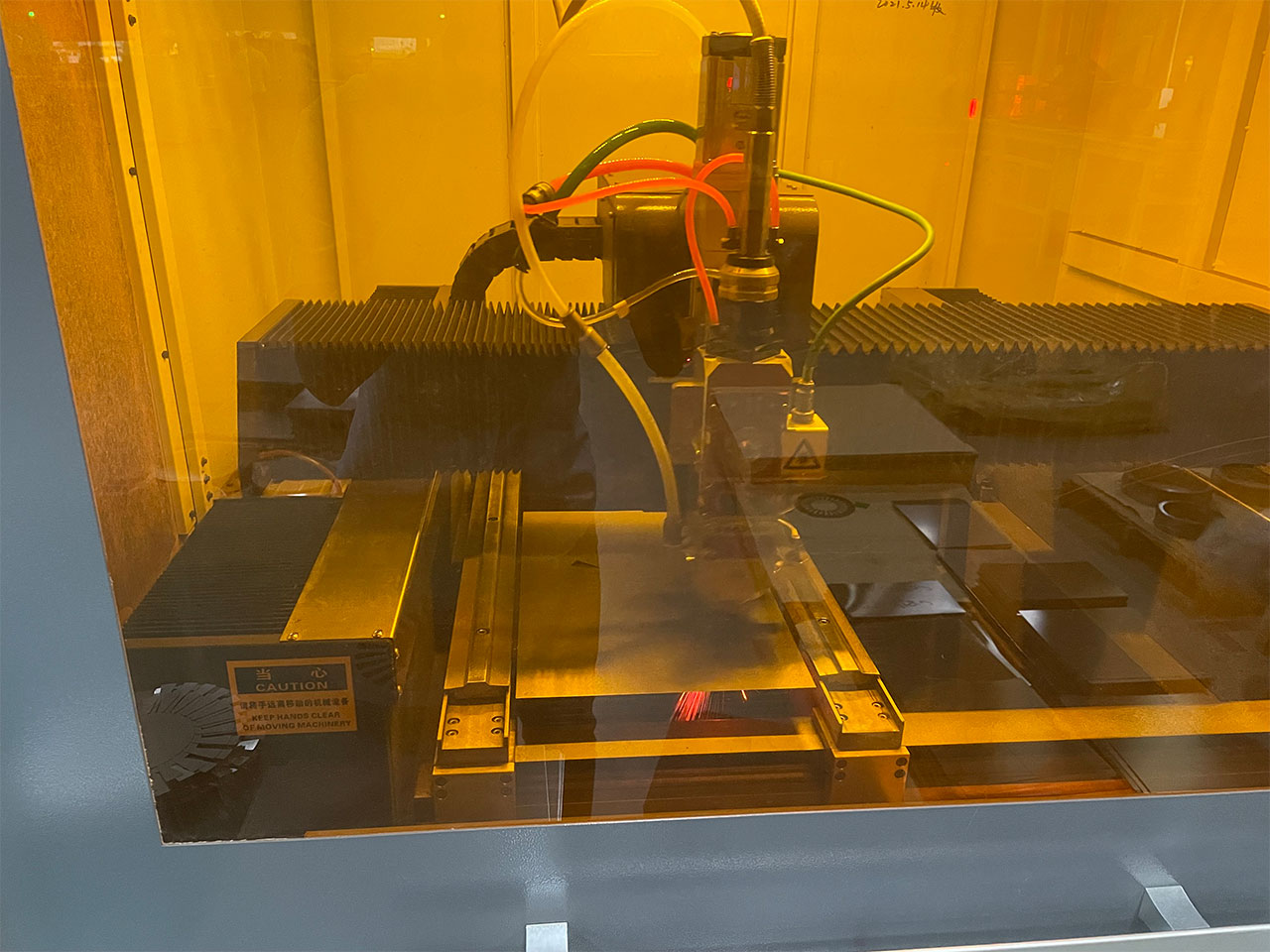

Laser Cutting

C

Ho kuta mohala o phahameng

B

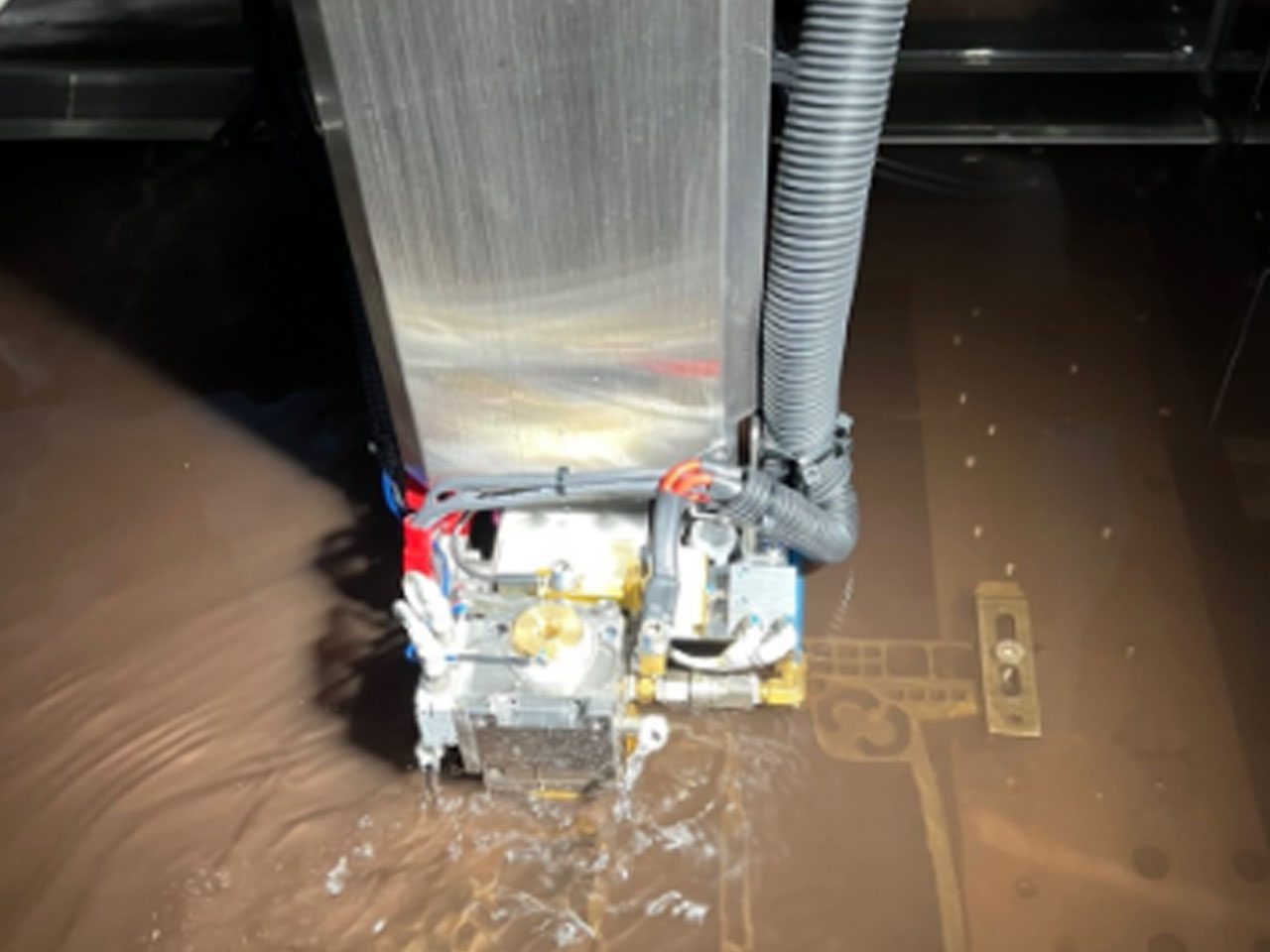

Ho kuta mohala o potlakileng

D

Re kenya mohala o tlase oa terata (re kenya mochini oa mofuta oa Sebibi ho tloha Japan)

Ho tsitsipana

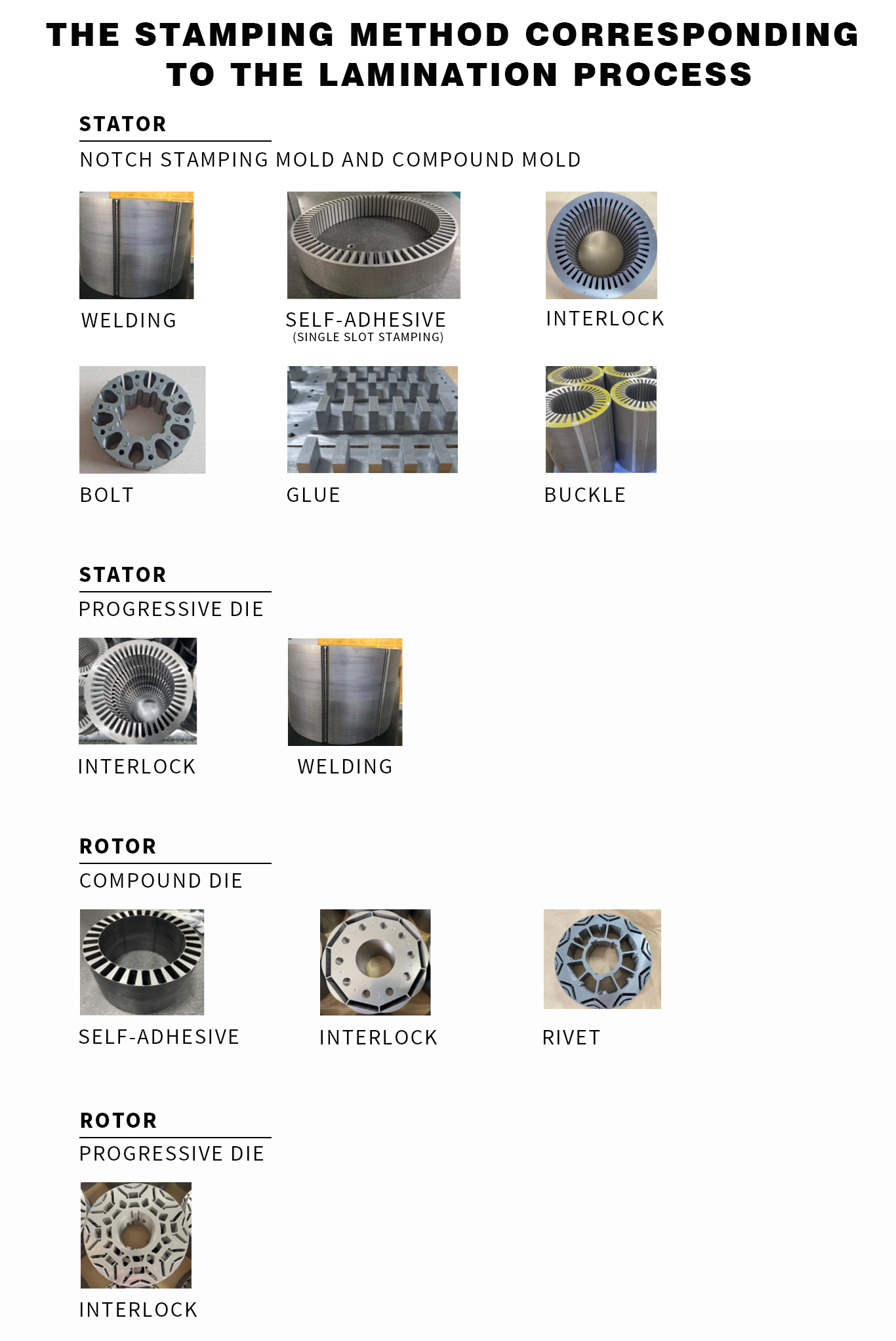

Re na le mefuta e fapaneng ea likhatiso ho fihlela litlhoko tsa hau tse fapaneng tsa ho reka.

Slot e le 'ngoe e le' ngoe

Tobetsa: 10t-16t-16t

Komporo ea tsela

Tobetsa: 40t-550T

E tsoela pele(Lebelo le phahameng)Ho tsitsipana

Lits'oants'o: 630t, 550t, 315t (Schuler),300T (AIDA),160t, 120t, 80t (Nidec)

Lithupelo tsa Trimte & Molemo

↓

A. Ke leboha lisebelisoa tse tsoetseng pele le tsa mahlale a tsoang Jeremanele Aida, Nidec ho tloha Japane,e re re hoLi-LOmiminotion tsa Molloindasteri e le 'ngoe e le' ngoe.

B.achielo

C.The Slot e le 'ngoe e tobetsa od2000mm max.

Slot e le 'ngoe e le' ngoe

Sesebelisoa sa: Notch Stamsing e shoa

Khaola leqephe la silicon ho hlokahala, 'me karolo e' ngoe le e 'ngoe ea tsona e tla ba maemong a hlokahalang. Slot e le 'ngoe e boreleli ke mokhoa o loketseng ho feta bakeng sa thuto ea limela tse nang le bophara bo boholo bo nang le bophara bo holimo le palo e kholo ea disampole.

Komporo ea tsela

Sesebelisoa sa: The Infround e shoa

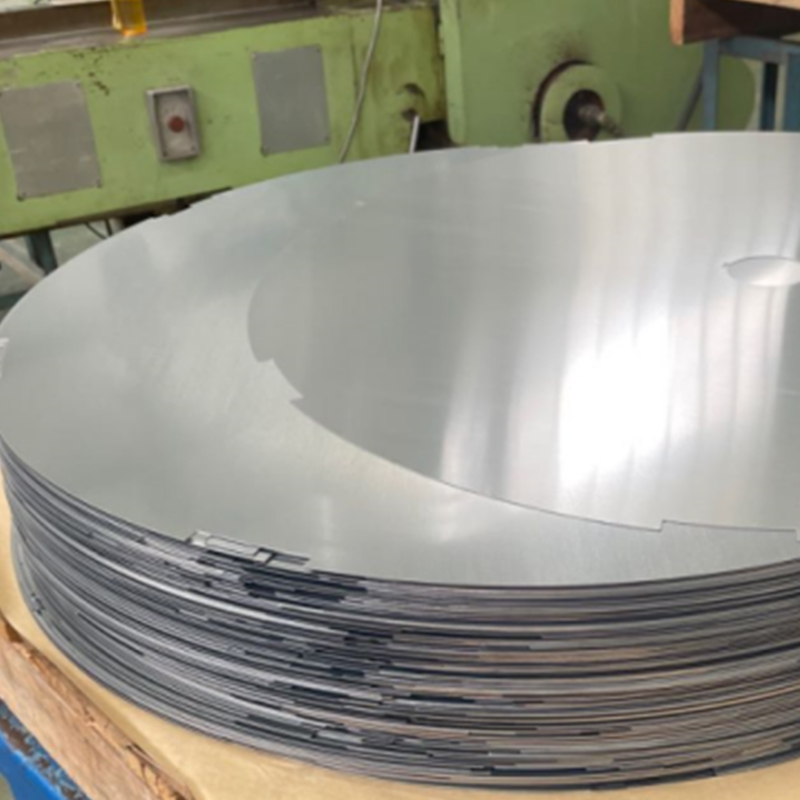

Reka lesela le lumellanang la silicon le lekanang ho latela boholo ba sehlahisoa se hlokahalang, ebe o theha likelimi tsa mamati le mehala ea marulelo le rotor. Ho na le mekhoa e 'meli ea ho fepa ka ho fepa metsi a batang a haloa ka liphallelo tse ling tsa likoloi, tse sa foleng, empa li ka boloka litšenyehelo tsa lintho tsa nama; E 'ngoe ke fepa e tsoelang pele ea likholomo, e nang le phallo e phahameng.DETE e tla sheba boemo ba setoko ha moreki a beha taelo, ebe o bala theko e molemohali ea ho etsa tumellano ea sethala le rotor. Ntle le moo, k'hamphani ea rona e na le tokelo ea boithati ka ho sebelisana 'moho le ho sebelisa chelete ea lipalesa tsa likoloi tse tsoelang pele.

E ntse e tsitsitse

Sesebelisoa sa: Lijo tse tsoelang pele

Mofuta oa mofuta ona o boetse o bitsoa hlobo e matla haholo e tšosang. E fapane le ea komporo ea komporo, e ka sebelisa likarolo tse loketseng tsa boitseba bakeng sa ho fepa, ho qeta ho ts'oasa le ho inkela hlobo.

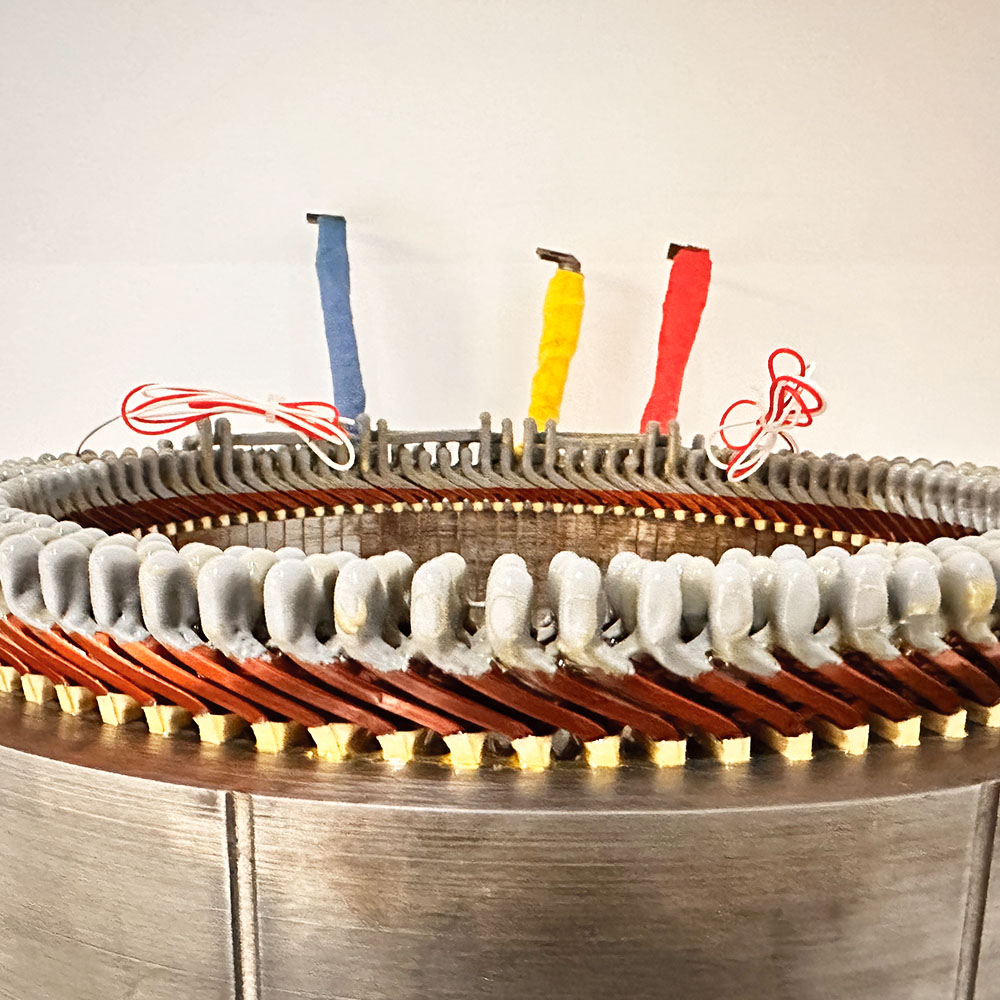

Ho na le mefuta e 'meli ea ho ingolisa. E 'ngoe ke ntlha e chitjallang bakeng sa boholo bo bonyenyane ba melami ea makoloi, e nang le litlhokahalo tse phahameng tsa terene. Li-stack ha li hloke ho hatelloa habeli ho lisebelisoa tsa ho hlakisa.the tse ling ke ntlha ea ho ingolisa, e hlokang khatello ea bobeli ho netefatsa hore e tiisa.

Kopano ea Naha e Khathatsang

Re fana ka terata e robileng le e meholo, likepe tse nyane tsa sampole le litlamong tse kholo tsa terata e le 'ngoe ea 2-8-4mmm. Hajoale lintlha tsa tlhahiso ea sehlahisoa ha li lumellane. Mehato ea mantlha ea 5-50.

Ho paka

Roate e tla kenngoa ka har'a lipalo ke Rivet, Interlock, itšoenyang, ho kenella ka bongata.

Rivet

Stacking Stacking hangata o sebelisoa bakeng sa rotor, ho na le Rivet Riven le Rivet Riven.

Welding

Ho paka ka thata ho sebelisoa bakeng sa li-lamintation ea Sprirato, ho na le ho palama ha eona le ho chechiseng ho taisa.

Glue

Ho pente hantle ka mokhoa o mong le o mong o nang le mabenkele le ho mo khomarela hammoho.

Interlock

Etsa lintlha tsa tokiso nakong ea ho makala, ho lula makoloi ho tlangoa ho tlamahanya ho ikamahanya le bona ka lintlha tsena. Interlock e ka ba mokoko kapa lisele tse chitja. E tsoela pele ho sebelisa mokhoa o tsoelang pele ho boloka ts'ebetso ea chelete le nako ea rot.

Boithati

Lintho tse bonahalang: B35a300-Z50A400-Z50A400-Z50A400-Z

Lintho tse ling li koahetse holimo, li tla qhibiliha 'me li hokahanya rotor e' ngoe le e 'ngoe e le' ngoe le setlama se seng le se chesang se futhumatsang pele. Ho itaola ho tla etsa lihlahisoa tse bonolo le ho feta.

Bolt

Bolt e sebelisoa bakeng sa sethala sa lipalesa ka bophara bo boholo bo kantle.

Buckle

Ho kenya litekete tsa Buckle ho sebelisetsoa tumellano ea liphoofolo tsa pula, ho na le li-sockles tse otlolohileng kapa li sesa.

Tlhahlobo

Lisebelisoa tsa rona tsa liteko li kenyelletsa ho mela, ho fokotsa tšepe ea tšepe, ho felloa ke tšepe, le Cmm e na le li-Brands.

Tlhahlobo e arotsoe likarolo tsa tlhahlobo ea pele, boipuso, tlhahlobo ea patrol le tlhahlobo ea hoqetela. Ho sa tsotelehe hore na mokhoa oa ho tsitsipalla ke eng, likotoana tsa pele tsa makoloi le karolo ea pele ea setakaneng sa lithunya le rotor e lokela ho romelloa feela ka mor'a tlhahlobo e fetisoa.

Packing

Ho latela litlhokahalo tsa bareki, ba li-stetors li na le likhoele tsa tšepe, mabokose a polasetiki a kenyelletsa sekotlolo, litloholo tsa seponche le pampiri ea seponche, jj.

Ha lengolo la likoloi le tšoanelehileng le sekaka sa polokelo ea thepa le rotor li phethehile, re tla ba arola ka seponche, re tla ba arola ka seponche sa thepa le ho pakela linyeoe tse seng tsa lehong bakeng sa thomello ea kantle ho naha.